IME offer vibration analysis services that are tailored to meet client specifications and regulatory standards.

Typical vibration analyzers and software are intended for monitoring machine condition over the longer term, but they require special training and investment that may not be possible in many companies.

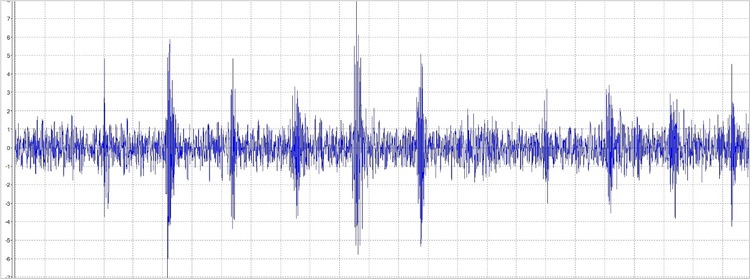

Understanding why vibration occurs and how it manifests itself is a key first step toward preventing vibration from causing trouble in the production environment.

But how can the plant maintenance professional tell the difference between acceptable, normal vibration, and the kind of vibration that requires immediate attention to service or replace troubled equipment?

When vibration is a problem?

All mechanical equipment has inherent vibration. Most industrial devices are engineered to operate smoothly and minimize vibration. In these machines abnormal, vibration can indicate problems or deterioration in the equipment. If the underlying causes are not corrected, the unwanted vibration itself can cause additional damage.

Most common cause of machine vibration:

- Imbalance

- Misalignment/shaft run out

- Looseness

- Wear