IME offer airborne ultrasound analysis services that are tailored to meet client specifications and regulatory standards.

Ultrasound technology offers a wide range of applications that can be used effectively in maintenance.

Application areas of Ultrasound are:

- Leak detection:

Ultrasound leak detection covers a wide range of leaks: pressure or vacuum and any gas. Sound dependent, ultrasound instruments detect turbulent flow produced as the fluid (liquid or gas) moves from the high-pressure side to the low-pressure side of a leak. Ultrasound leak inspection is especially beneficial in areas where there is a saturation of gases or where a wide variety of gases, pressurized vessels and vacuum processes exist. For this reason ultrasound leak detection is used in many facilities for safety, environmental, energy or quality assurance programs. - Steam Trap Inspections:

When steam traps leak or fail, it can be extremely costly in terms of product quality, safety and energy loss. There are differences in the way particular steam traps work (for example, inverted bucket trap versus float and thermostatic trap). Our equipment makes it easy to sense these differences and readily determine operating conditions while steam traps are on-line. - Valves:

When valves leak or fail, it can be extremely costly in terms of product quality, safety and energy loss. Valve operation affects the way fluids will flow through a system. There are great differences in the way particular valves work (for example, control valve versus safety valve). Our ultrasound equipment makes it easy to adjust for these differences and readily determine operating conditions while valves are on-line. - Ultrasonic Bearing & Mechanical Inspection:

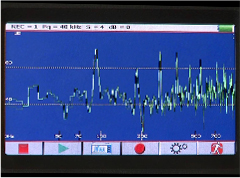

Ultrasonic inspection of mechanical equipment with out equipment has many advantages. Ultrasound inspection provides early warning of bearing failure, detects lack of lubrication, prevents over lubrication and can be used on all bearing speeds (high, medium and low). - Ultrasonic Electrical inspection:

Ultrasound inspection may be performed on both open access and enclosed electrical equipment at all voltages (low, medium and high).