Our Asset Management and Reliability Services team leverages strong industry knowledge with continuous improvement processes, reliability techniques and asset intelligence systems.

Maintenance is one of the controllable areas with higher impact on operating costs of capital-intensive industry. Reliability is the key to achieving an efficient and effective maintenance, becoming a critical business function that positively impacts plant productivity, client service, business risk, product quality, safety and environment resulting in higher profitability.

If the organization is experiencing more failures than it should, it is necessary to implement asset productivity improvement programs. This proven strategy is an approach to business based on common sense, within a framework of key tools of reliability engineering analysis and business analysis processes.

At IME we have highly qualified and trained to join our clients in the implementation and commissioning of the different maintenance programs such as RCM, RCA and maintenance planning.

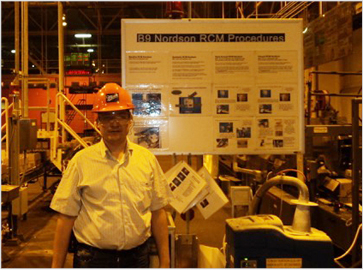

Commissioning of RCM

The Reliability Centered Maintenance is a methodology for developing highly effective maintenance plans, which through a systematic review of possible failures with different teams of subject matter experts, define the most relevant tasks for future prevention or mitigation. The Commissioning Process consists of:

- Enroll the company personnel in the maintenance plan development

- Load maintenance (CMMS) Software plans derived from RCM analysis

- OT implementation with technical crafts

- Work order closure procedures

Commissioning of RCA

We recommend a multi-functional team of people participate in the root cause investigation process. IME provides a support role as needed to ensure that the investigation continues to move forward, appropriate evidence is collected, cause-and-effect relationships are being captured to the appropriate level of detail, solutions are connected back to specific improvements in work process and the entire investigation is being documented efficiently and clearly. This coaching (support) role ensures a complete investigation by keeping the group consistent and moving in the direction of completion (solutions).

Commissioning Maintenance Planning

This methodology seeks to implement best practices in the area of planning and scheduling maintenance work, greater staff productivity, optimize workloads, greater availability of equipment and higher quality and more cost effective maintenance.

In the Start up we will guide the staff to implement the cycle of the 5 planning stages, these stages are:

- Post-Maintenance Day Staging

- Planning & Scheduling Staging

- Stockrooms Staging

- Pre-Maintenance day Staging

- Maintenance day Staging